& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

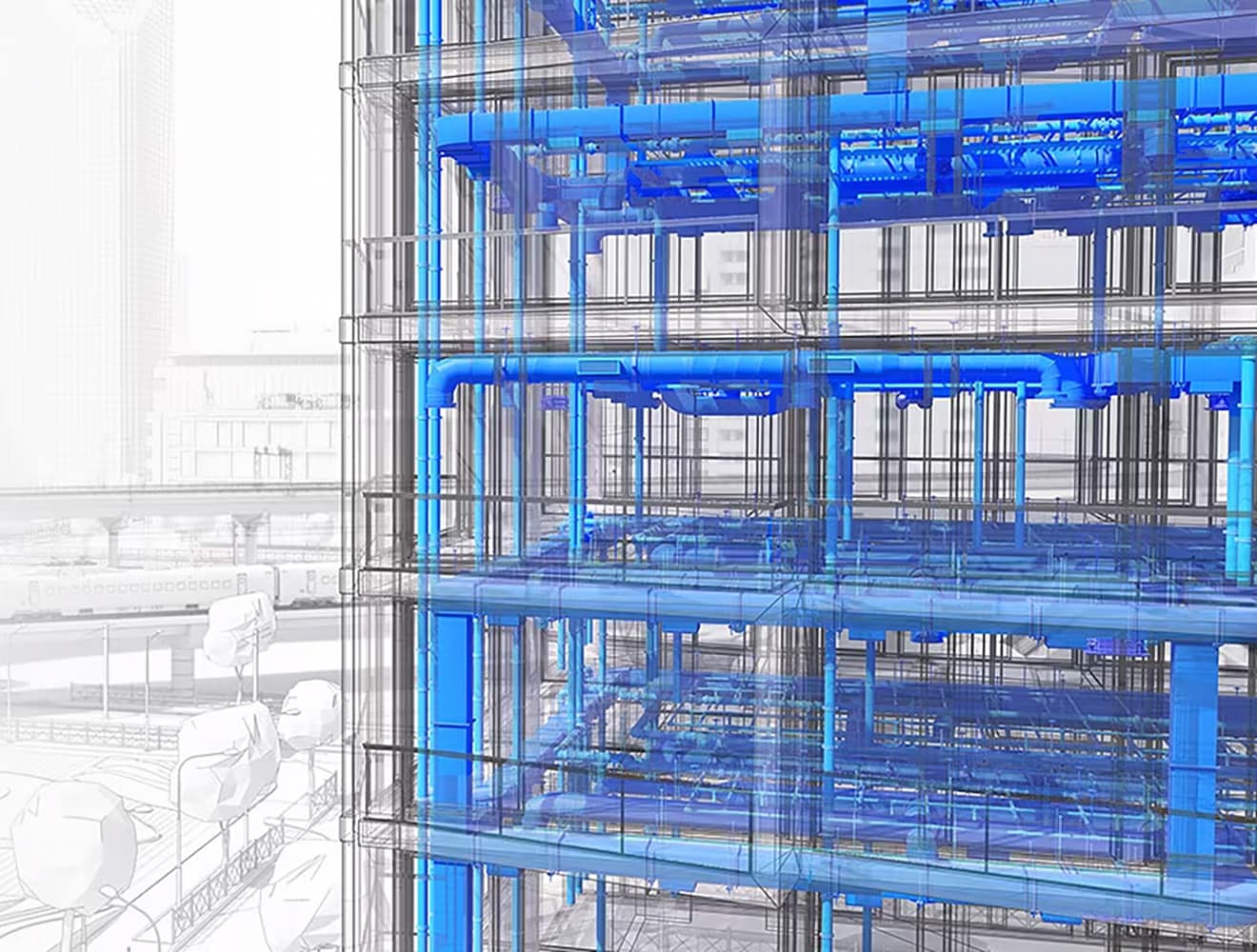

MEP engineers are under more pressure than ever to design and deliver building systems that balance performance, cost, and constructability. With BIM, design teams more effectively, design more sustainably, and raise the bar for industry excellence to keep their teams and firms one step ahead.

Of BIM projects report savings on labor, collaboration, and/or materials.

Of users say BIM has made them more productive.

Report BIM reduces the risk of problems during fabrication and construction.

– Bimal Patwari, Founder & CEO of Pinnacle Infotech

Using a single source of data enables them to provide higher-value outcomes.

TDIndustries' technology journey is changing the game and leading to greater client satisfaction.

Image courtesy of TDIndustries.

With streamlined design process, Pinnacle improved operational efficiency on ambitious projects.

Image courtesy of Pinnacle Infotech.

Max Fordham has seen significant improvements in project outcomes since moving to into BIM.

Image courtesy of Laurian Ghinitoiu/BIG.

For the Kirlin Group, BIM tools are reducing errors, preventing clashes, and keeping projects on track.

Bravida built a streamlined process with BIM and integrated engineering workflows. The results: nimble teams, high performance, and reduced costs.

Image courtesy of Bravida.

With BIM, multidisciplinary teams work securely and collaboratively within a unified design environment, providing a single source of truth for coordinating trades, sequencing project phases, raising issues and detecting clashes.

MEP engineers can use the data in BIM to conduct advanced simulation and analysis, with real-time insights as a project evolves.

Image courtesy of BNIM.

BIM-based tools enable engineers to integrate systems design and fabrication detailing workflows to better understand design impacts to a high level of detail and with respect to client requirements, local and regional codes, manufacturability, and installation.

BIM helps you automate and collaborate at scale. The latest advances support seamless data exchange between all building design disciplines. Working with BIM can cut weeks, even months from project schedules.

Image courtesy of BNIM.

Identify errors earlier on, coordinate changes, and reduce rework down the line with a centralized 3D model where all stakeholders have visibility.

Create a single, digital source of truth that all stakeholders can access and contribute to. Connect your model via the cloud giving the entire project team access to accurate information whenever they need it.

Advanced analysis plus parametric design tools support optioneering and optimization from concept through shop drawings.

Use design automation to eliminate repetitive tasks and to reach optimized design solutions faster.

Autodesk has formed a strategic alliance with Schneider Electric to enable electrical designers influence building design with more sustainable energy systems in mind. Schneider Electric’s Advanced Electrical Design for Autodesk Revit allows electrical engineers to make more informed decisions and play a more strategic role in building projects.

Powerful BIM and CAD tools for designers, engineers, and contractors, including Revit, AutoCAD, Civil 3D, Autodesk Forma, and more

Plan, design, construct, and manage buildings with powerful tools for Building Information Modeling.

Cloud-based design co-authoring, collaboration, and coordination software for architecture, engineering, and construction teams. “Pro” enables anytime, anywhere collaboration in Revit, Civil 3D, and AutoCAD Plant 3D.

MEP detailing and fabrication software—available as Fabrication CADmep, Fabrication CAMduct, Fabrication ESTmep

Navisworks Manage, Navisworks Simulate software and the Navisworks Freedom 3D viewer for 5D analysis, design simulation, and project review.

BIM stands for Building Information Modeling, and it is a collaborative process that allows MEP (Mechanical, Electrical, and Plumbing) engineers to create and manage digital representations of the physical and functional characteristics of a building. BIM for MEP engineering specifically focuses on designing, analyzing, and optimizing MEP systems within a building

Design and Modeling: BIM software lets MEP engineers create detailed 3D models of mechanical, electrical, and plumbing systems. These models include information such as dimensions, materials, and equipment specifications.

Clash Detection and Coordination: BIM enables clash detection, where the MEP models are checked for clashes with architectural or structural elements. This helps identify and resolve conflicts early in the design phase, reducing rework and coordination issues during construction.

Quantification and Cost Estimation: BIM software can extract quantities and measurements from MEP models, allowing for accurate cost estimation and material takeoffs. This helps in project budgeting and procurement processes.

Analysis and Simulation: BIM tools provide simulation capabilities to analyze MEP systems' performance, energy efficiency, and sustainability. Engineers can simulate airflow, lighting, HVAC systems, and energy usage to optimize design and make informed decisions.

Documentation and Communication: BIM facilitates the generation of detailed construction documentation, including drawings, schedules, and specifications

BIM contributes to cost efficiency in MEP coordination through clash detection, improved coordination, accurate quantity takeoffs, value engineering, efficient design iterations, and enhanced communication.

1. Enhanced Collaboration: BIM enables better collaboration between MEP engineers, architects, contractors, and other stakeholders, improving coordination and reducing conflicts.

2. Improved Efficiency: BIM streamlines MEP workflows, reducing errors, rework, and project delays. It allows for faster design iterations and facilitates efficient decision-making.

3. Clash Detection: BIM's clash detection capabilities help identify and resolve conflicts between MEP systems and other building elements before construction, saving time and costs.

4. Cost Savings: BIM enables accurate quantity takeoffs, cost estimation, and material optimization, leading to cost savings during the construction process.

5. Performance Analysis: BIM allows for simulation and analysis of MEP systems, optimizing energy efficiency, sustainability, and overall performance.

6. Improved Documentation: BIM automates the generation of detailed construction documentation, reducing errors and improving communication between project teams.